Kiln Glass... Making my Rounds! (Part 2, 12.15.18)

There are many ways I manipulate glass to get my signature glass water rounds. Many techniques involve cutting circles. My glass studio is great — except in winter, when it’s pretty cold. (I’ve figured out most of my way around the cold:)

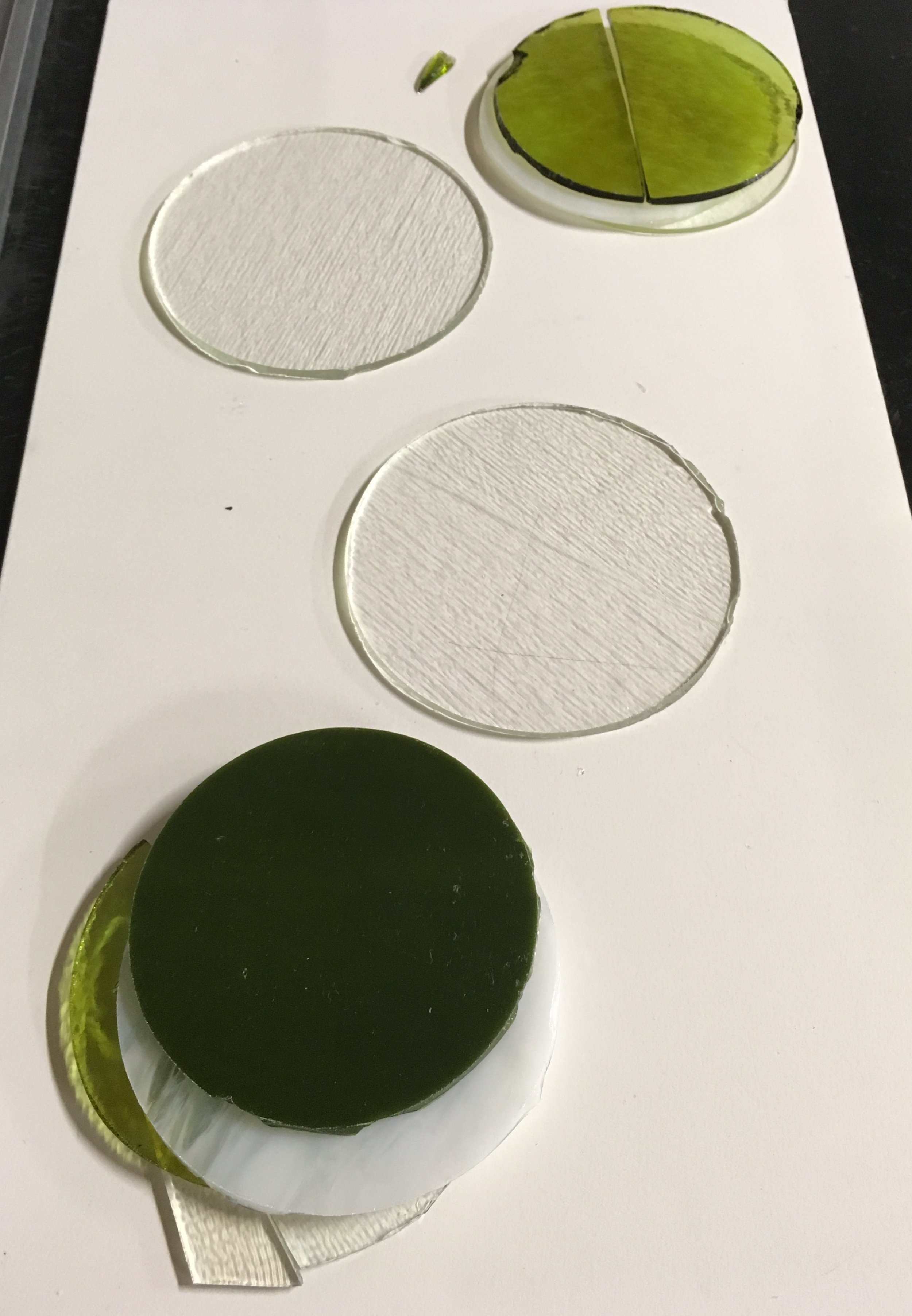

Glass doesn’t love to be cold when you’re working with it — especially when cutting circles. This is when I may heat it up before cutting it — like here.

What happens when cutting circles with cold glass or not paying close attention — more cracks & uneven edges. (These were small test pieces.)

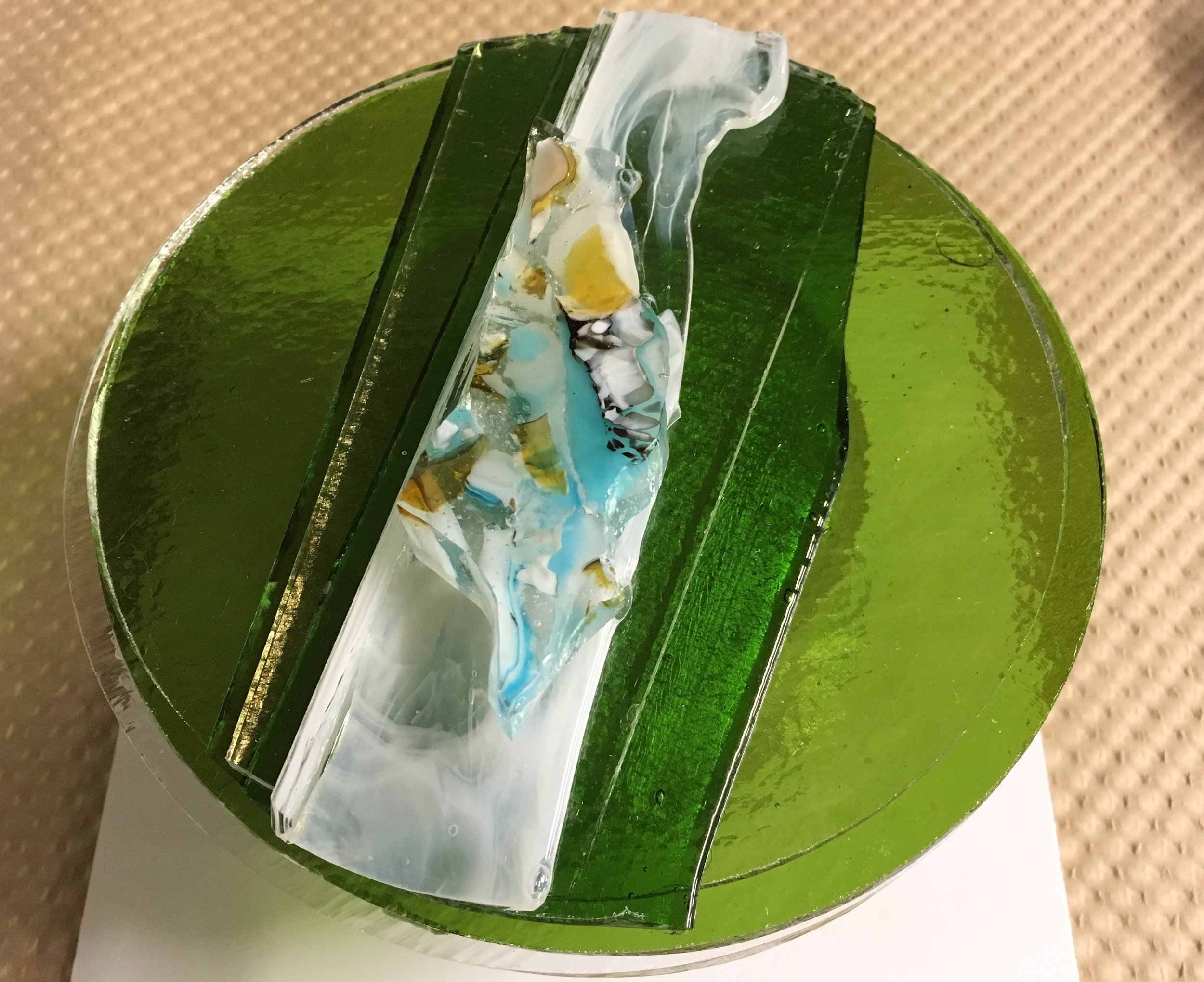

This is one way I make my glass water rounds — before I add a lot more glass to top. (Chunk on very top has been pre-fired several times.)

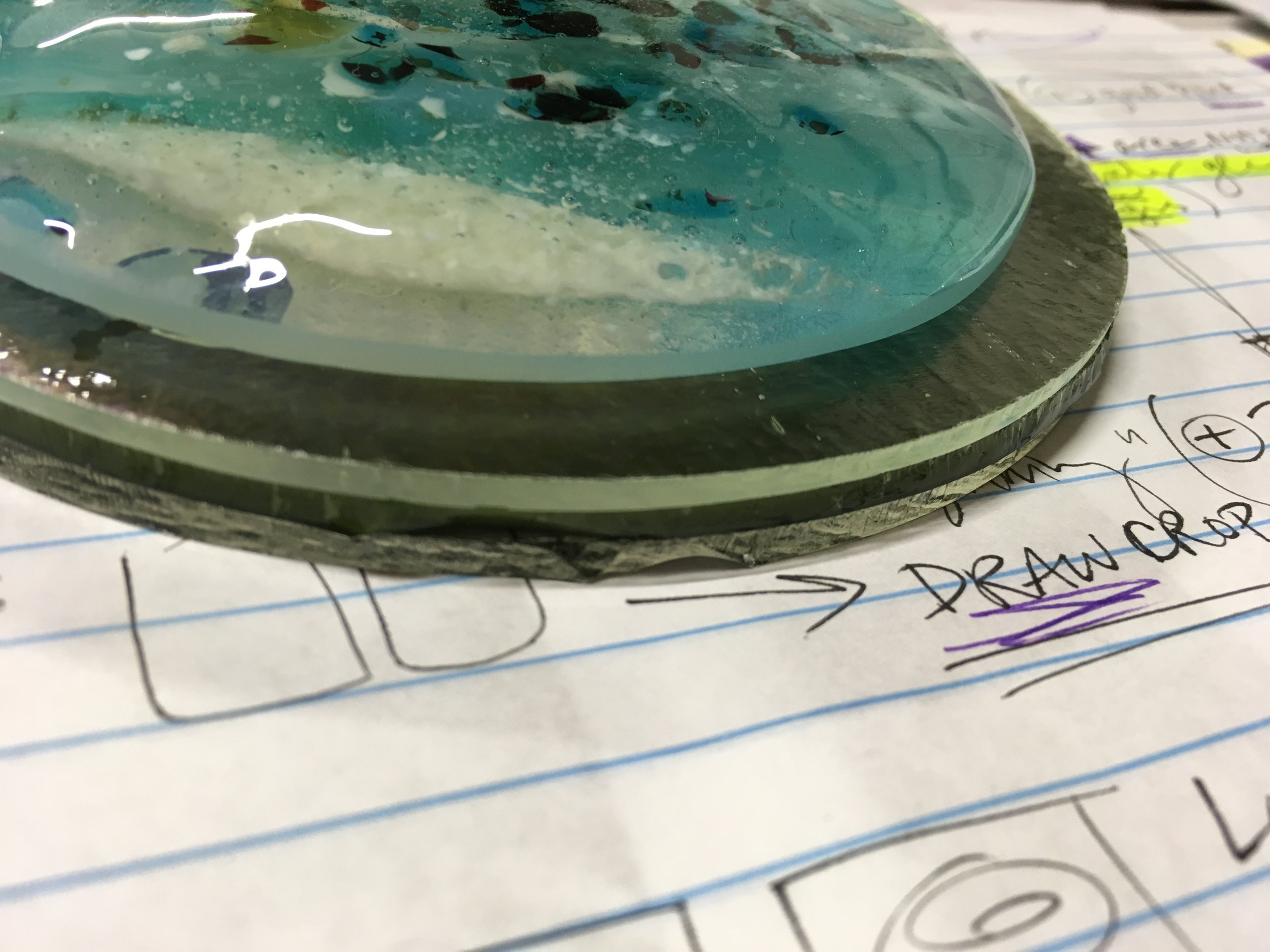

Side view of glass water round layers — bottom 3 are raw sheet glass, and the top has been fired several times already — and edges sanded on belt sander. (I take a lot of notes!)

Rounds in one of the last firing stages.

Here’s another technique where entire surface gets covered with glass frit — before longer, hotter firing. The “white” is actually mostly clear.

These are bird’s eye view of two newer water rounds — in the kiln. (Work will debut at McColl Center for Art + Innovation exhibition during my residency that starts next month:)